Hear from Metcal application expert Paul Wood how the new Scarab can reduce costs and risk with touchless desoldering. Video captured at SMTAI.

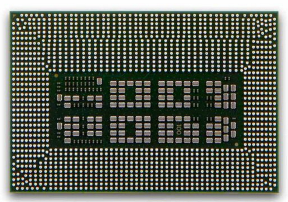

Today’s manufacturers of printed circuit boards (PCBs) are strongly quality driven, but even among those operations that are able to drive yields near or even above 99%, the huge volumes associated with applications such as smartphones and tablets could still leave them with thousands of boards per week that come off the assembly line damaged and in need of rework.

Since the cost of these PCBs can be well over US$200 each, most manufacturers and OEMs consider it vital to develop an effective process for working to reclaim these boards and minimize scrap PCBs—and the resulting losses—in their operations.

As boards and components continue to shrink in size, costs continue to escalate and global consumer demand continues to intensify, it is becoming increasingly challenging for manufacturers to clean faulty boards in their rework process. As such, automated contactless cleaning – previously a specialized process utilized by only a small segment of the market – is fast becoming mainstream for most rework manufacturers, often driven by the need for manufacturers to remain competitive, but by the adamant demand of their OEM customers as well.

Continue reading about the challenges facing rework manufacturers and the evolution of cleaning methods in the PCB rework process.