A soldering iron is an invaluable tool when it comes to hand soldering tasks. But even the best soldering station will eventually fail if it is not used correctly.

A soldering iron is an invaluable tool when it comes to hand soldering tasks. But even the best soldering station will eventually fail if it is not used correctly. We have provided helpful advice for your soldering iron tips before, but here are nine tips that will help keep your soldering iron itself working for years to come.

Tip #1: A Microprocessor Controlled Soldering Iron Will Protect the Iron and the Work

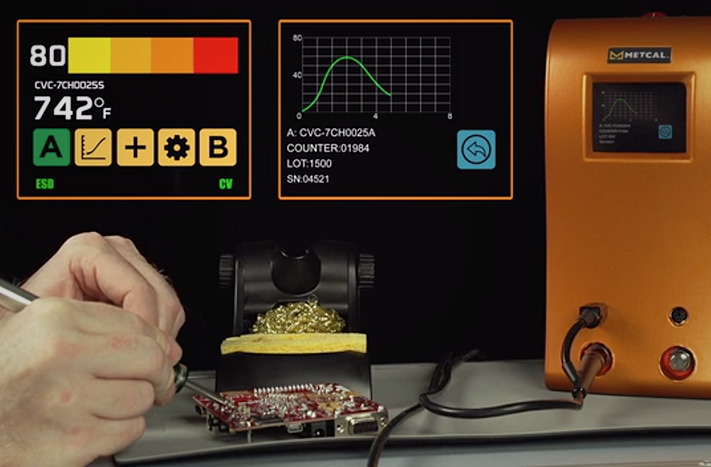

Today there are microprocessor controlled soldering stations that will automatically control the temperature of the iron. In regular use, a constant power soldering iron can create sudden temperature swings during thermal operations. Microprocessor-controlled stations eliminate the temperature spikes that can stress the heating element.

Tip #2: Avoid Excessive Heat

One of the main components of a soldering iron is the heating element (or heater coil). While most elements will provide a long life of service, they do eventually fail. One way to avoid premature failure is to run the iron only as hot as it is required to do the work.

Keep your operating temperature in a range that works for your solder, but not higher. For typical (non-lead-free) solder, this temperature is around 300°C.

Tip #3: Turn Off the Soldering Iron When Not in Use

Turning the soldering iron off when not in use will save wear and tear on the components of the iron and extend its life. You can make your iron last longer by remembering to turn it off when you know it’s not going to be used for a period of time.

There are soldering stations on the market today that feature auto-sleep functionality. These irons can help to preserve a soldering iron as well as provide for a safer work environment by automatically powering down when not in use.

Tip #4: Check Your Temperature When Changing Solder Types

Lead-free solder requires a higher temperature for proper operation than standard solder types. But when you switch back to standard solder, be sure to adjust your temperature. Otherwise, you run at a temperature higher than what is required, which, as we discussed, will eventually shorten the heating element life.

Tip #5: Keep the Power Cord out of Harm’s Way

Make sure that the power cord for your soldering iron is stored correctly away from the work area. Having a power cord that comes in contact with a hot soldering iron can not only damage the iron, but it is also hazardous. This can be easily avoided with proper organization and workplace set up.

We should mention that other items should be kept away from the business end of a hot soldering iron as well. This includes long hair, skin, falling hats, falling glasses, and clothing. In fact, if it isn’t solder or used on a circuit board, it should probably be kept away from the soldering iron.

While we are talking about the work area, make sure that there is proper ventilation. You don’t want to breathe in the fumes that soldering creates as part of the process. Avoid eating while soldering as well, since your hands can become contaminated with solder flux and paste.

Tip #6: Keep It Clean

For proper soldering operation, everyone knows they need to keep the tip clean and properly protected with solder when it is stored. But don’t overlook the fact that the rest of the iron needs to be kept clean as well. Material that collects on the hot part of the iron but not part of the tip can still impact soldering iron performance.

Some soldering irons will have a darker discoloration on its metal shaft or barrel after the first few initial uses. This should be considered normal.

Tip #7: Don’t Abuse the Soldering Iron

Things can get heated (pun intended) when solder doesn’t behave as it should. It is natural to apply more force to the soldering iron when this happens, and beginners will often do so. But this should be avoided, as it creates an unneeded strain across the body of the soldering iron.

A heavy force can damage the heating element, sensor array, cartridge mount, and other key pieces of a modern soldering station. The problem is compounded if the force is applied at an angle or across the length of the iron.

If force needs to be applied to the work to get the job done, consider using a tool better designed for blunt force applications.

Tip #8: Be Gentle When Changing Tips or Cartridges

If they receive proper maintenance, tips and cartridges can provide a long service life. But eventually, they will need to be placed, and with some iron types, they can be difficult to remove. Be sure that you understand how the tip attaches to the iron.

Many tips will actually screw into the base, which means pulling them out with force could damage the iron. If a tip is stuck in place, avoid placing pliers or other tools directly on the shaft. These can damage the shaft and the heating element itself.

If the shaft does need to be supported, wrap it with a protective layer before applying a light holding force. Be sure that the iron is off and cool before attempting to hold it.

Tip #9: Know When to Replace a Soldering Iron

No matter how much care you give a soldering iron, it will eventually need to be replaced if it sees a lot of use. The good news is that an iron can last a long time if it is properly cared for and stored. But once the iron starts showing its age, the proper course of action is to replace it.

A damaged or worn iron can be thermally erratic, creating unpredictable behavior. An overheated iron can destroy components, so inspect your iron before use and replace one that shows damage.

With the right care, a soldering iron can provide a long service life. An advanced soldering station can increase solder tip life and allow for more efficient soldering performance. We carry a variety of soldering, desoldering, and reworking tools, featuring SmartHeat® Technology.

Contact us today to see how we can make your hand soldering efforts a success.