One of the biggest challenges in manufacturing electronics today for military and defense is soldering high thermal mass circuit boards like radio frequency (RF) boards.

RF components create a lot of heat, requiring thermal management solutions for high reliability. High-performing components can be sensitive to heat-induced failures, with failure rates increasing with every degree increase in temperature. With temperature increases as little as 10 degrees Fahrenheit, the risk of component failure can double, and exponentially increase thereafter with each degree increase. To maximize reliability, heat spreaders and large ground planes are incorporated into PCB designs, drawing heat away from sensitive components.

RF-type PCB designs also require electromagnetic interference (EMI) grounding and RF shields to protect sensitive components from high RF frequencies. Though these design elements guard against transmitting and receiving radio interference, they also add to the board’s overall thermal mass, acting as additional heat spreaders.

Between the heat management built into the designs and the mass of the EMI grounding and RF shielding, RF boards pose a unique manufacturing hurdle.

Topics Covered:

Why Hand Soldering High Thermal Mass Boards Is a Huge Challenge

Why Resistive Heat Soldering Systems Are Not Powerful Enough for High Thermal Mass Boards

How Manufacturers Imagine the Ideal Soldering Process

How Inductive Heating Technology Conquers High Thermal Mass Soldering

Why Inductive Heating Soldering Systems Beat Resistive Systems When Working with High Thermal Mass Boards

How Metcal SmartHeat® Achieves Accurate Temperatures with Self-Regulating Cartridges

How to Reduce Solder Joint Failures with the Added Process Control of Connection Validation™ (CV) Technology

Metcal Adjustable Inductive Heating Systems Offer Power and Flexibility

Why Metcal Soldering Systems with Inductive Heating Technology Are the Solution for High Thermal Mass RF Boards

Why Hand Soldering High Thermal Mass Boards Is a Huge Challenge

When heat is applied to make a solder joint, these ground planes and heat spreaders immediately disperse that heat (as they are meant to do), drawing the heat away from the joint. This process lowers the tip temperature, and the soldering station must apply more power to the joint. With many soldering systems, the power to maintain the tip temperature in these cases is simply not available.

Here’s the dilemma: How do you solder a board full of heat-sensitive components when the board is designed to spread heat?

To meet the demands of modern PCBAs like RF boards, military and defense manufacturers need soldering systems with the power required to keep the tip temperature high enough to bring the solder to liquidous consistently.

This can be difficult with RF boards. If the system does not have enough power, the soldering station fights the heat spreaders. And loses. Which results in inconsistent (and therefore unreliable) solder joints. And when it comes to military and defense manufacturing, solder joint quality cannot be left to chance.

Why Resistive Heat Soldering Systems Are Not Powerful Enough for High Thermal Mass Boards

The trouble operations have with PCBAs like RF boards is built right into their soldering systems.

Many military and defense manufacturers are still using common resistive heating soldering systems. Resistive heating systems work perfectly well for less demanding soldering applications but often cannot meet the demands of high thermal mass boards.

Resistive heating systems create heat by passing an electrical current through a material that resists the current. The amount of heat generated depends on the amount of current passing through the material and the resistance of that material to the current.

This is a common method of creating and transferring heat, but not particularly efficient:

Downsides of Resistive Soldering Systems

- Slow initial heat up

- Prone to overshoot their set temperature on heat up and recovery

- Struggle to maintain tip temperature during heavy load applications

- Slow recovery to set temperature after soldering a joint

How Manufacturers Imagine the Ideal Soldering Process

Especially within the military and defense sector, manufacturers dealing with high thermal mass boards need soldering solutions that will nearly guarantee:

- Ramp up to the desired tip temperature is fast, with no temperature overshoot

- Enough power to solder a high thermal mass board

- Power is there to make solder joints quickly

- Recovery time is short, with no overshoot

- Temperature is accurate and specific to their needs

How Inductive Heating Technology Conquers High Thermal Mass Soldering

There is an alternative to resistive heating in modern soldering systems: inductive heating.

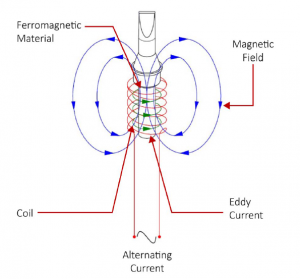

With induction, heat is created when an alternating electrical current is passed through a coil, creating an alternating magnetic field around an object made of an easily magnetized material like iron, nickel, cobalt, and their alloys.

When magnetized by the alternating current, the atomic poles of the metal alternate in the direction of the frequency of the current. Heat is then created through hysteresis losses and Eddy current losses.

Eddy currents flow mainly on the surface of the metal (called the skin effect). Because of this, the surface of the metal heats up first and very quickly. And more heat is generated by increasing the frequency of the electrical current, not the amount of electrical current. This makes for a very fast and efficient heating system.

For in-depth information about inductive vs resistive heat soldering systems, see our white paper: “How it Works: Inductive vs. Resistive Hand Soldering Systems.”

Why Inductive Heating Soldering Systems Beat Resistive Systems When Working with High Thermal Mass Boards

Inductive heating systems offer many advantages over resistive systems, especially for applications like heavy mass RF boards:

Faster Initial Heat Up

Unlike a resistive system where heat is being created by pushing current through a metal that resists that current, inductive systems are much faster to reach their set point temperature. This is a major benefit of a technology that more efficiently creates and transfers heat and is a major benefit to the user’s productivity.

Shorter Dwell Time

Dwell time is the time the hot soldering iron must “dwell” on the component to make a quality solder joint and is one of the most important factors when dealing with high thermal mass applications.

The object is to keep dwell time as short as possible. The longer the soldering iron takes to heat the solder to liquidous, the more time that heat has to spread to other (potentially heat sensitive) components.

But on high thermal mass boards, the heat spreaders are constantly drawing heat away from the work area, making it difficult to control the temperature at the joint.

This is where inductive heating systems really shine. They have enough power, enough available heat, to quickly bring the joint to the intended temperature and maintain that temperature, predictably.

Faster Recovery

As with fast initial heat up, inductive systems recover to their set point temperature after each successful joint very quickly, thanks again to the efficiency of Eddy currents and the skin effect.

How Metcal SmartHeat® Achieves Accurate Temperatures with Self-Regulating Cartridges

Metcal has been the leader in inductive heat soldering systems since its Silicon Valley beginnings in 1982. All Metcal systems use inductive heat for superior heating power and performance.

Metcal has been the leader in inductive heat soldering systems since its Silicon Valley beginnings in 1982. All Metcal systems use inductive heat for superior heating power and performance.

Metcal takes the advantages of inductive heating a step further with their patented SmartHeat® technology. First introduced with the MX Series soldering stations, SmartHeat® is a combination of inductive heating and proprietary self-regulating cartridges that literally control tip temperature at the molecular level.

This is How SmartHeat® Works

As the high-frequency current is being passed over the heating element, and flows along the skin of the magnetic alloy, the alloy quickly heats to what is known as its Curry Point temperature. The Curry Point is the temperature at which the alloy loses its magnetic properties. Reaching the Curry Point, the alloy loses its magnetic properties, thus eliminating the skin effect. The tip then cools slightly, the temperature passes back below the Curry Point, and the magnetic properties are restored. The skin effect returns immediately, and heating begins again, repeating the cycle.

This heating and slight cooling process cycles over and over, maintaining the tip temperature at the Curry Point of the alloy, with only a +/- 1 °C variation at idle. This is what Metcal means by a “self-regulating cartridge.”

By creating soldering cartridges with different Curry Points, Metcal can offer extremely accurate heat at a variety of fixed temperatures, with virtually no overshoot.

How to Reduce Solder Joint Failures with the Added Process Control of Connection Validation™ (CV) Technology

Nowhere is it more important to ensure quality solder joints than in the military and defense sector. The proper functioning of products and components is critical.

What is the best way to predict the future failure of a solder joint? Soldering station operators are the first line of defense, visually inspecting each joint as it is made. Later, board-level and system-level tests may be run but catching a problem in that stage of production requires rework and creates waste. With each step in this process, if the failure is not detected, the time and cost to repair that failure increases tenfold. Detecting potential problems early in the process also reduces the number of failures in the future.

The best time to spot a future solder joint issue is as early as possible, at the soldering station.

Metcal Connection Validation (CV) Soldering Systems Give Immediate Feedback on Solder Joint Quality

Connection Validation™ (CV) soldering systems from Metcal give the operator immediate closed-loop feedback when a quality solder joint has been made, right on the handpiece. There is no need to rely solely on visual inspection or operator intuition.

CV systems measure each joint’s intermetallic compound formation (IMC) as it is being made. If the joint passes validation, a green LED ring light on the handpiece illuminates, telling the operator it is time to move on.

CV systems measure each joint’s intermetallic compound formation (IMC) as it is being made. If the joint passes validation, a green LED ring light on the handpiece illuminates, telling the operator it is time to move on.

Connection Validation technology also provides traceability information over time, with the ability to monitor and record system power demand, tip temperature, solder time, and IMC formation of each joint. This detailed information is invaluable for detecting and solving problems on the soldering line.

This is the ultimate process control, and the best way to qualify solder joint quality right on the benchtop.

For a detailed explanation of Connection Validation™ technology and IMC formation, watch this video.

Metcal Adjustable Inductive Heating Systems Offer Power and Flexibility

Some manufacturers prefer the flexibility and versatility of adjustable temperature soldering systems. Metcal’s answer is the GT Series best-in-class adjustable temperature systems with the power of inductive heating.

Some manufacturers prefer the flexibility and versatility of adjustable temperature soldering systems. Metcal’s answer is the GT Series best-in-class adjustable temperature systems with the power of inductive heating.

The GT Series uses patented hardware and software to control tip temperature through precise management of the alternating current applied to the system. The temperature sensor is built into the cartridge tip, allowing for continuously modulated and accurate control and feedback to and from the unit. This level of control makes it possible to create specific profiles for preheating the tip and ramping up temperatures, for optimal solder results.

Since process control is always important, especially in military and defense manufacturing, the GT systems include administrative lockout features. Three temperature presets can be saved, but overall control of the system can be password protected. So once the ideal temperature for an application is determined, no matter what that temperature is, it can be set, saved, and locked in.

Why Metcal Soldering Systems with Inductive Heating Technology Are the Solution for High Thermal Mass RF Boards

Hand soldering high thermal mass boards like RF boards is a challenge. Tightly packed, layered boards with heavy ground planes and heat spreaders offer unique obstacles that require equipment capable of delivering exact levels of heat quickly and consistently.

Inductive heating soldering systems like the Metcal MX, CV, and GT offer:

- Fast heat up and temperature recovery for greater productivity

- High thermal performance, with no overshoot, delivering consistent heat when needed

- Short dwell times for increased output and less damage to heat-sensitive components

- The ease and flexibility of precise temperature control

- High efficiency delivering reduced energy costs

Whether you are in the military and defense space or the private sector, if you are having trouble meeting the challenges of high thermal mass applications like RF boards, Metcal Soldering Systems with inductive heating can be the solution for your operation.

For more information on MX Series, Connection Validation™ (CV), the GT Series, or any of the Metcal portfolio of soldering systems with SmartHeat® inductive heating systems and heat-on-demand, go to Metcal.com to explore further.

![]()

Metcal, an OK International brand, is a benchtop solutions innovator, leading the way in hand soldering, convection rework, fume extraction, and fluid dispensing. Metcal breakthroughs have empowered global OEM and electronics assembly customers in contract manufacturing, automotive, aerospace, medical devices, industrial, and military sectors since 1982.