Solder tip life is a hot topic. Check out this example of how soldering station sleeper stand can reduce wattage by up to 30%.

Solder tip life is a constant discussion among users of hand soldering for almost all applications. Whether you’re in production, rework, or R&D, the cost of tips and their longevity impacts the ROI of your overall soldering investment. While operators almost always want the tip to be hot, hot, hot, and all the time, using a soldering iron sleep stand can significantly improve the life of your solder tips.

When used when the handpiece is idle, a Solder Sleep Stand automatically reduces the power supplied to the hand piece, leading to:

- Reduced idle temperatures

- Slower chemical reactions

- Less inter-metallic formation

- Less de-wetting

- Longer tip life

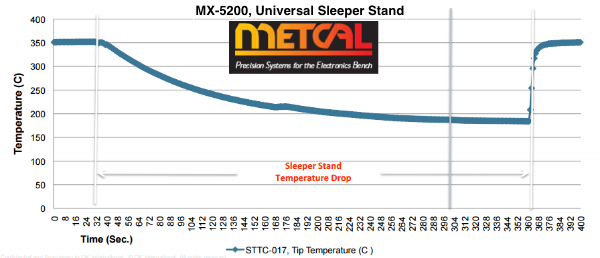

Take a look at this chart that illustrates the effect of using the sleeper stand for just a few minutes.

You can see how this can significantly reduce the power consumption as well, meaning for a production environment, it can affect your total ROI.

Theoretical Example:

If you have 5 soldering irons each in production using on average 40 watts per hour over an 8 hours day your consumption is:

5 irons X 40 watts = 200 watts X 8 hours (1 day) = 1600 watts per day

Potentially a soldering iron can spend up to 50% of its time in the stand between operations; if the stand is a sleeper stand, the idle wattage is reduced to around 5 watts.

The equation now becomes;

5 irons X 40 watts = 200 watts X 4 hours (1 day) = 800 watts + 5 irons X 5 watts = 25 watts X 4 hours (1day) = 200 watts = 1000 watts per day

That’s saving 600 watts a day, nearly 30%!!! Luckily, Metcal got you covered, as every MX or MFR series soldering system comes with a Soldering Sleeper Times Stand. If you have misplaced yours, consider getting yourself a new one!