In the world of electronics, devices seem to keep getting smaller, faster, smarter, and more functional. To make this happen, designers and manufacturers have needed to overcome a number of challenges, including problems related to increasing amounts of heat generated within electronic devices.

Today’s electronic devices, smartphones, automotive electronics, and LED lighting are just a few examples that have challenged designers to devise new methods of managing heat. Common heat management solutions include metal heat dissipating structures such as:

- Highly metallized components,

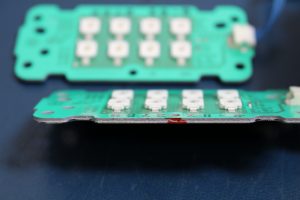

- Circuit boards with multiple layers of copper, and

- Insulated metal substrates (IMS).

These solutions work great to dissipate heat away from thermally sensitive components, so your devices will continue to function reliably. But they create real problems in the hand soldering manufacturing process.

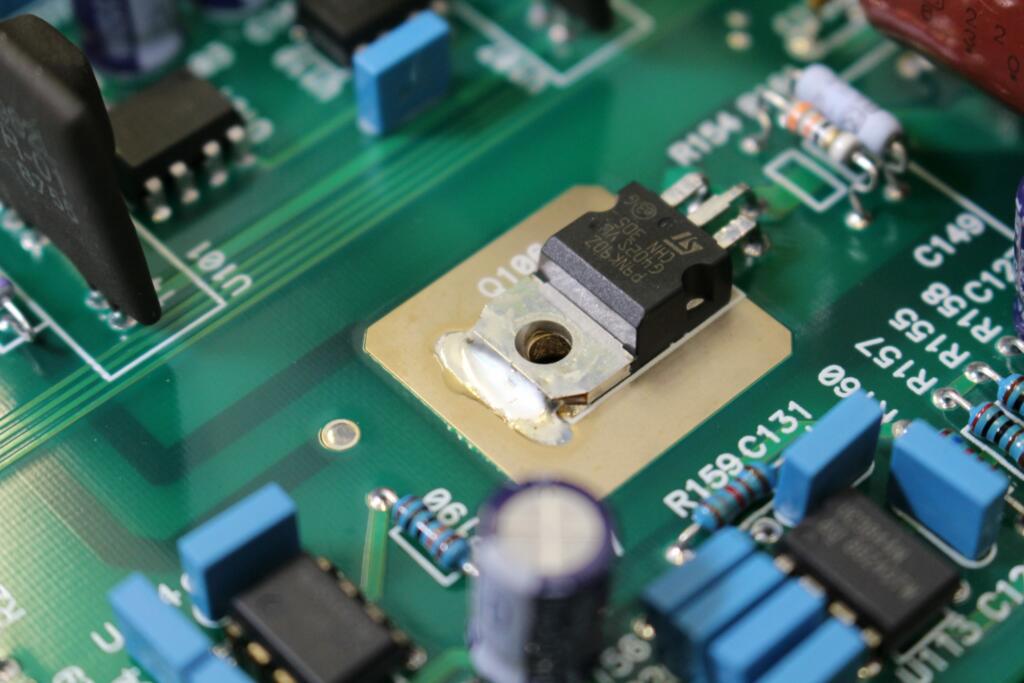

Highly metalized components (TO220) and circuit boards create a heat distribution effect that pulls heat away from the tip of the soldering iron, making it difficult to deliver the appropriate amount of heat to create a good solder joint.

Technicians might compensate for these soldering challenges by:

- Extending dwell time – the time they hold the hot tip of the soldering iron to the solder joint

- Raising the temperature at the tip of the soldering iron, and

- Preheating the circuit board – attempting to solder while the board is hot

These compensation methods not only decrease tip life but can also result in damage to circuit boards and thermally sensitive components, while creating safety issues for soldering technicians. A better solution for high thermal demand soldering is METCAL™ GT series adjustable temperature inductive soldering systems. METCAL™ GT Systems:

- Take advantage of rapid heating indicative of induction – they’re based on induction heating technology.

- Utilize patented hardware and software to control and manage solder tip temperature – with temperature sensor, and (PID) feedback loop to the microcontroller, they produce continuously modulated temperature control.

- Allow the operator to create tip temperature profiles for preheating and ramp up to achieve optimal soldering results.

METCAL™ GT90 and GT120 Systems – Built for Today’s Demanding Electronic Devices.

For more information on METCAL™ GT systems, browse our website, or reach out to your local rep or distributor today. For more information on High Thermal Demand Soldering, see our White Paper titled Inductive Soldering for High Thermal Demand Applications.