One of the easiest assumptions to make regarding soldering systems is “Higher wattage equals better performance.” It makes sense. The higher the wattage, the more “power” there is to generate the heat needed for a successful solder joint, right?

Maybe not.

Metcal has discovered there are three factors that influence soldering system performance, and wattage is one of them. But not #1.

Metcal Performed an Experiment

The engineers at Metcal wanted to test the new Metcal GT120 and GT90 inductive heating soldering systems, to see how the system performance would stack up against the competition. They gathered a group of comparable resistive systems from their top competitors to determine which would perform best on a series of test joints under controlled conditions.

The Performance Test Metrics

Their comparison tests focused on three key soldering performance metrics:

- Time to temperature

- Dwell time

- Recovery time

Time to Temperature

This is the amount of time it takes a soldering station to reach its setpoint temperature. Time to temperature is a valuable metric, considered lost time in the manufacturing process. Fast heat-up speed means increased productivity, especially over multiple shifts.

Dwell Time

Dwell time is the time it takes a soldering iron to solder a joint. Dwell times can vary significantly among soldering systems, as some systems do not have the power required to maintain tip temperature during the heat transfer of the soldering process. This is especially true in high thermal demand applications, like in the Metcal test scenario. Longer dwell times mean a loss in productivity and can lead to damage of heat-sensitive components on the PCBA.

Recovery Time

This is the length of time needed to bring the soldering iron back up to its set point temperature after the heat loss of the soldering process. Like time to temperature, it is important a system has enough power to recover quickly. And, like time to temperature and dwell time, a short recovery time is desired to maximize productivity.

The Experiment Setup and Procedure

Seven identical test loads were machined from copper to represent heavy loads and mimic the challenges of soldering to a ground plane. A thermal couple was connected between the load and a port on the Metcal data acquisition system. The engineers recorded and stored the temperature output.

To run each test, a small bead of solder paste was applied to each joint, to maximize heat transfer between the soldering tip and the load. The loads were first cooled to about 24 degrees C before each run of the experiment.

For each test run, the soldering system being tested was brought up to a tip temperature of 400 degrees C. The iron was placed on the first thermal load, at a set angle, until the temperature of that load reached 250 degrees C (lead-free solder melts at 217 degrees C). The iron was then immediately moved to the next load. This was repeated until all seven test loads were soldered.

The timings and tip temperatures of all seven loads were measured and recorded.

The Systems Being Tested

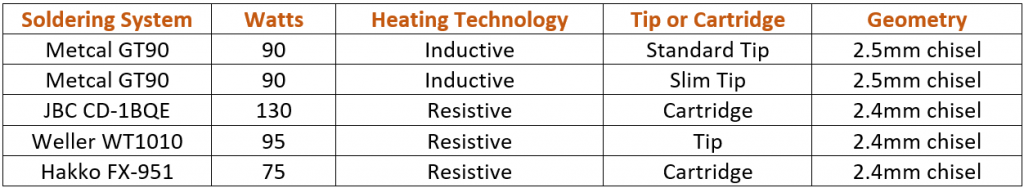

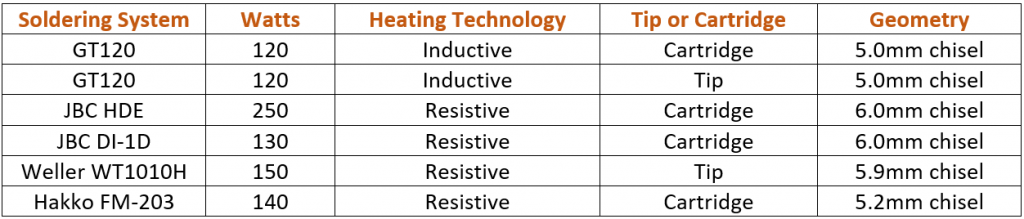

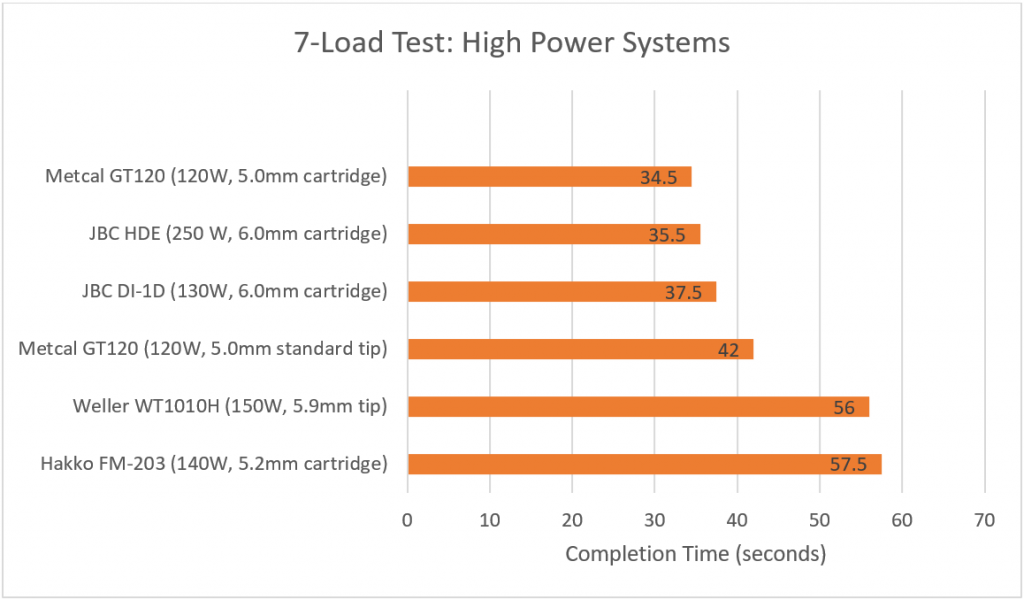

The systems were tested in two groups of comparable power levels.

Group One included systems from 75 Watts to 130 Watts, with 2.4mm – 2.5mm chisel tips and cartridges (depending on what the manufacturer offers).

Group Two consisted of systems between 120 W and 250 W, with 5mm – 6mm chisel tips and cartridges.

(For complete information on the testing, see the Metcal whitepaper “Inductive vs. Resistive Heating Technology Used in Soldering Systems: A Performance Comparison”)

Resistive vs Inductive Heating Soldering Systems

The main difference between the Metcal GT120 and GT90 and their competitors is in how they generate and transfer heat. Most soldering systems use resistance heaters, while the Metcal units use a patented inductive heating system.

Resistive Heating in Soldering Systems

Heat is generated in a resistive heat system by electrical energy passing through a material that resists the flow of electrons. The amount of heat produced depends on the amount of current and the electrical resistance of the material through which the current is flowing.

The heating element in a typical resistive system is built into the cartridge or is designed to be separate and further from the tip.

Inductive Heating in Soldering Systems

Heat is generated in an inductive heat soldering system by passing an alternating current through a coil to create an alternating magnetic field. When a ferromagnetic material is magnetized in that alternating field, heat is generated. As the frequency of the alternating current increases, so does the amount of heat.

The heat flows mainly along the surface of the material due to a phenomenon known as the “skin effect.”

(For complete information on how inductive heating works, see our whitepaper, “How It Works: Inductive Soldering vs. Resistive Soldering Systems”)

The Test Results

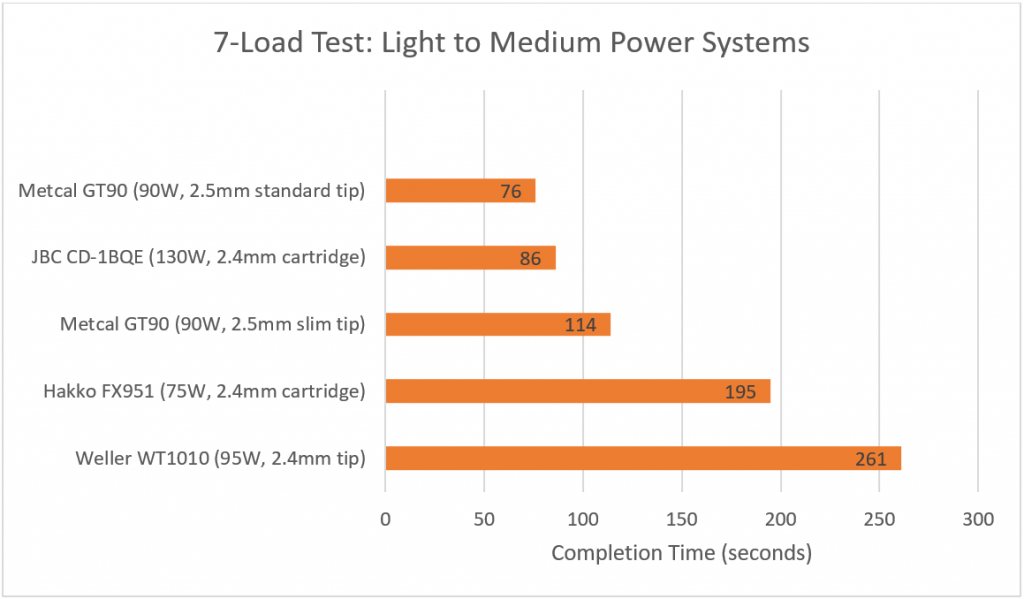

Here are the results of the 7-load test for all systems, ranked from fastest to the slowest system. Take special note of each system wattage, the heating technology, and whether a cartridge or tip was used:

Conclusions Drawn: The 3 Factors that Influence Soldering System Performance

The test results show there is a correlation between overall performance and three factors (in this order):

- Heating technology (resistive vs. inductive heat)

- Distance between the heating element and the tip of the soldering iron (cartridge vs. tip)

- Power rating of the soldering system (the wattage of the unit)

1. Inductive Heating Beats Resistive Heating

Metcal found that heating technology is the top factor in determining system performance. The test results clearly show inductive heat systems beat resistive heat systems, even systems of higher wattage. For instance, the 90-watt inductive heat GT90 with just a standard tip beat all resistive heat systems, whether they used tips or cartridges.

This is due to how each technology works. In resistive systems, heat is generated by a heater coil, then conducted to the tip. This two-piece design has greater thermal resistance and is less efficient than inductive heating.

The heating element is built directly into the tip in an inductive system. Eliminating the need to transfer the heat between separate pieces offers greater thermal performance, as direct heat is applied to the joint.

Also, inductive heating systems gain an advantage in that the heat energy travels along the skin of the metal. This is much more efficient than heating the entire heating element and tip in a resistive system.

2. Shorter Distance Between the Heater and the Tip Offers Superior Performance

The second most important factor is the distance between the heater and the tip. The shorter the distance, the better the performance.

The clearest example of this from the test is where the two GT120 systems went head-to-head, one with a cartridge and one with a tip.

Cartridges outperform tips because they have a heater built-in. Tips are cheaper than cartridges but add an element to the system, physically separating the heater from the soldering tip. This lowers thermal efficiency and ultimately performance.

An exception to this rule seems to be when the GT90 with a tip beat a 130-watt JBC CD-1BQE with a cartridge. This is more an indication of the superiority of inductive heating than an anomaly in the “cartridges beat tips” rule.

3. The Power Rating Isn’t Everything

The third factor is system wattage. In several cases, the wattage of the system was not as important as whether the heat was generated through inductive vs. resistive technology. For instance, the inductive heating 120-watt GT120 outperformed the 250-watt and 130-watt JBC resistive systems.

Final Thoughts

When comparing soldering systems, most users will focus on power. But as we’ve seen, power isn’t necessarily the most important factor in evaluating performance and maximizing throughput. If we focus on the essential metrics of hand soldering (time to temperature, dwell time, and recovery time), we confirm that heating technology and tip/cartridge configuration are even more important.

These findings confirm Metcal’s thinking when designing the GT Series adjustable heat soldering systems. The GT120 and GT90 are:

- Faster and more responsive than resistive systems due to the superior thermal performance of inductive heating technology

- Designed to use cartridges that integrate the heater and tip, for virtually no thermal resistance

- More energy efficient than resistive systems, achieving better performance through lower wattage

Add to this the versatility of an adjustable temperature system, intuitive user interface, password protection, and small footprint, and you have a superior benchtop hand soldering solution.

For more information on the Metcal GT120 and GT90 inductive heating, adjustable temperature soldering systems, go to Metcal.com.

To see more test results comparing the GT Series to other systems on time to temperature, dwell time, and recovery time, see the “Metcal GT90 and GT120 Inductive Heating Technology” infographic.

GT Series Resources

GT120 Data Sheet | GT90 Data Sheet | GT120 and GT90 Quick Start Guide

GT Series Cartridges & Tips Guide

GT Series Frequently Asked Questions | GT Series Training Videos