We often get detailed questions from Process Engineers about how SmartHeat® really works, and whether fixed (or stable) head soldering stations or variable heat is what they need.

The Basics of SmartHeat® and the Heater Elements

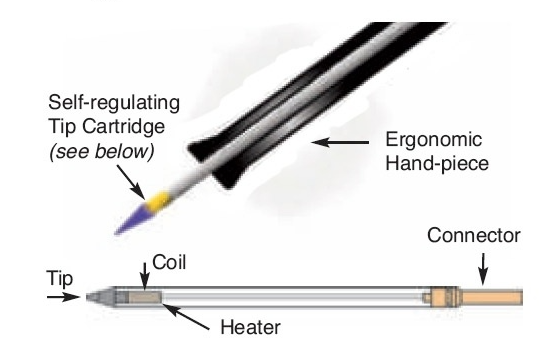

SmartHeat® heaters consist of two basic elements; a high-frequency alternating current (AC) power supply, and a heating element. The biggest difference between a conventional soldering station which consists of a ceramic or wire wound heating element, separate sensor and temperature control circuitry, and a Metcal heater is that the Metcal heating element itself is capable of heating and then maintaining a predetermined temperature. In other words “the heater is the sensor.”

The Metcal heater depends upon the electrical and metallurgical characteristics of two different metals; copper is a material with high electrical conductivity and the other is a magnetic material with high resistivity.

When the Metcal heating element is energized by the high-frequency alternating current (AC) power source, the current will automatically begin to flow thru the conductive copper core of the heater. However, as the AC current continues to flow, a very useful physical phenomenon occurs, the current flow is directed to the skin of the heater assembly. This is of course known as the “Skin Effect”, it drives the majority of the current through the high resistance magnetic layer, causing rapid heating.

The Curie Point

As the outer layer reaches a certain temperature (which is controlled by its heater alloy formula) it loses its magnetic properties. As most of you know this “certain temperature” is the Curie point. The Curie point temperature is when the “skin effect” begins to decrease again, permitting the current back into the conductive core of the heater starting the whole cycle over again.

The selection of a material with a fixed Curie point results in a heater that will produce and maintain a specific, self‐regulated temperature; and a heater that requires no calibration and responds directly to thermal loads. When a thermal load is applied to the tip, the heater temperature drops, and the power supply responds with the power required to correctly solder the joint on the board.

A Big Fish Analogy

Just imagine that you are on the ice fishing trip of a lifetime. It is a perfect January day in the northern reaches of Minnesota, the air is a crisp 35-below and the fish are biting. After a long day on the ice, you retire to your fishing shack with its inviting pot belly stove. You snuggle into your bunk for what should be a long night’s sleep, but to your surprise, every 15 minutes you wake up with either a sweaty back or a frozen face. That’s right; half of your body is cooking on the stove side while the other half is freezing against the cold wall. You look across the cabin at your fishing buddy and he is sound asleep, seemingly immune to the hot/cold cycles on your side of the cabin. So after staring at him for another hour, you notice his sleeping bag is changing colors from light to dark. You can’t help yourself and you wake him up.

Just imagine that you are on the ice fishing trip of a lifetime. It is a perfect January day in the northern reaches of Minnesota, the air is a crisp 35-below and the fish are biting. After a long day on the ice, you retire to your fishing shack with its inviting pot belly stove. You snuggle into your bunk for what should be a long night’s sleep, but to your surprise, every 15 minutes you wake up with either a sweaty back or a frozen face. That’s right; half of your body is cooking on the stove side while the other half is freezing against the cold wall. You look across the cabin at your fishing buddy and he is sound asleep, seemingly immune to the hot/cold cycles on your side of the cabin. So after staring at him for another hour, you notice his sleeping bag is changing colors from light to dark. You can’t help yourself and you wake him up.

“How can you be so comfortable in this cabin? You scream. He rubs the sleep from his eyes and explains. “I work for a textile company and I’m testing out a new sleeping bag material.” You push him for more details, “how does it work?” Well, he says, “It senses my body temperature and automatically adjusts its heat and cold absorption to keep my body comfortable.” “But what about the hot stove, you ask? And the changing colors?” He responds. “The material is designed to maintain my body temperature, so it absorbs the heat from the stove and circulates it around my body, when it senses a cold spot from the wall it directs more heat energy to maintain my comfort level, once it reaches body temperature it turns white and stops absorbing and waits for a temperature change, goes dark and then it starts the whole cycle again.”

This analogy is close to how SmartHeat® works. The “material” is made of a metal alloy which has the ability to absorb energy from an electric field and turn it into heat. When the alloy reaches a certain temperature, it stops absorbing energy and using the fishing analogy, it turns white and its temperature stops rising. When a solder joint draws heat from the heater, the alloy reacts immediately by becoming “dark” again to take on more energy and reheat.

Once more, but a car analogy for you car buffs!

We all know that SmartHeat® responds to changes in the thermal loads of a solder joint and cruise control responds with the correct amount of power to complete the operation, the same way your car’s cruise control maintains the set speed over a long drive. Here the vehicle controls are similar to the SmartHeat® system; your cruise control is your fixed temperature cartridge and your tachometer is similar to a net power meter.

We all know that SmartHeat® responds to changes in the thermal loads of a solder joint and cruise control responds with the correct amount of power to complete the operation, the same way your car’s cruise control maintains the set speed over a long drive. Here the vehicle controls are similar to the SmartHeat® system; your cruise control is your fixed temperature cartridge and your tachometer is similar to a net power meter.

On level ground, you set the cruise to 70 mph, as your car encounters hills and valleys the cruise control works to vary the output power of the engine to maintain that 70 mph that you set. How can you verify the engine’s changing output? It is very simple, look at your tachometer. As your route takes you up a hill the cruise control tells the engine to increase power (revs) to meet the 70 mph that you preset. At the top of the hill, you are still going 70, as you start down, the cruise control tells the engine to reduce the power (revs) so that you are not exceeding your preset and it saves you gas and hopefully from a speeding ticket.

Hope these explanations have you thinking about how SmartHeat® can work for your applications!